Compelling content attracts a devoted audience.

With a well-crafted strategy, it not only conveys your brand's value but also cultivates a loyal viewership.

Develop a marketing strategy centered around the customer

Market Research

User Experience

Digital Marketing

SEO Services

Captivate your audience with the power of social media marketing.

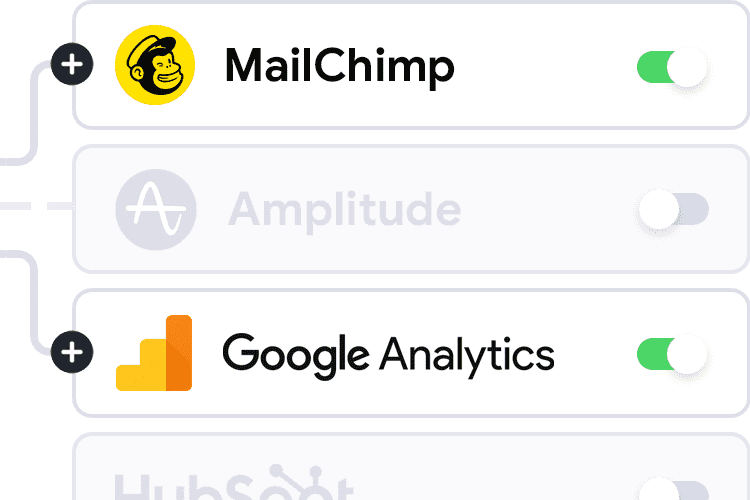

Marketing Integrations

By implementing marketing integrations, businesses can synchronize their marketing activities, gain a holistic view of customer interactions, and optimize their campaigns for better results.

Enhance Engagement

Refers to the process of improving and increasing the level of interaction and participation between a brand or business and its audience or customers.

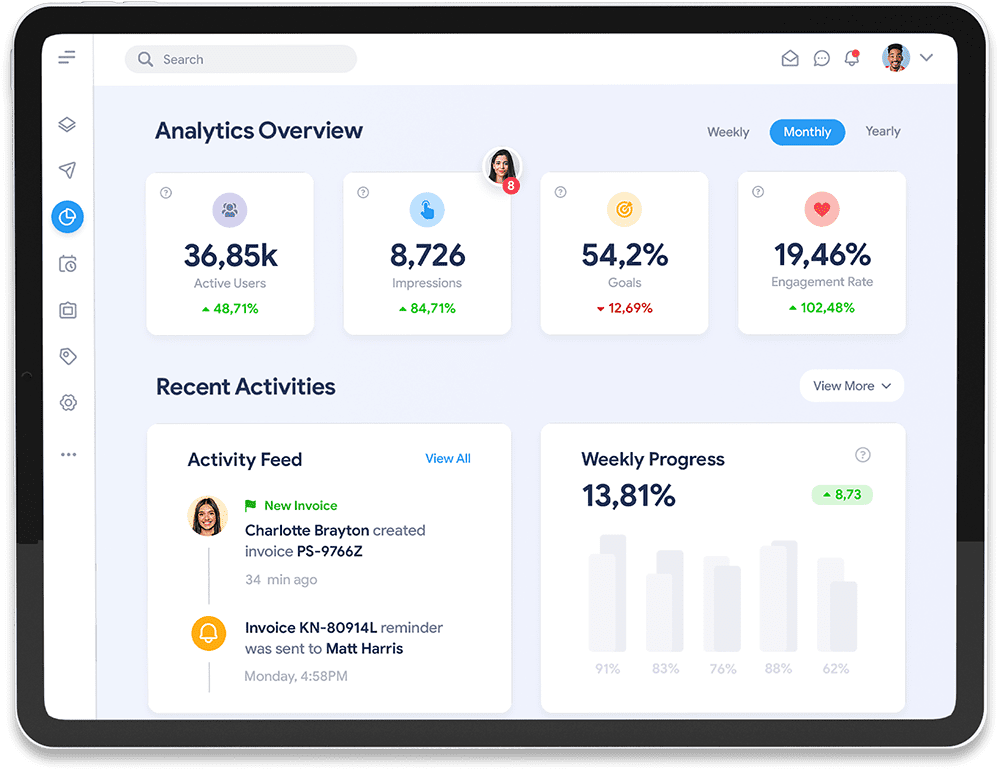

At a single glance, witness your business revenue soar

Our tailored approach is designed to maximize profitability and drive sustainable growth, allowing you to see substantial returns on your investments with just a quick assessment.

Market Research

Market research involves a systematic approach to gather, analyze, and interpret relevant data about your target market, competitors, and industry trends.

User Experience

Well-designed User Experience enhances customer satisfaction, builds loyal customer bases, and helps businesses gain a competitive edge.

Digital Marketing

Digital marketing provides businesses with the opportunity to reach a global audience, target specific demographics, track campaign performance, and adjust strategies in real-time.

Web Development

It requires a combination of technical expertise, creativity, and problem-solving skills to deliver websites and web applications that meet the needs of users and businesses alike.

Brand Design Identity

It helps build trust and loyalty with customers, differentiates the brand from competitors, and sets the tone for how the brand is perceived.

SEO & SMM Services

Combining SEO and SMM services can be highly effective for businesses looking to maximize their online presence and reach their target audience.

Extensions & Addons

Improved Productivity

Customizable Dashboard